Few things encapsulate the need for workplace safety and injury prevention as well as the popular 4-letter abbreviation from way back in 2012. As we all know, YOLO.

And since we only live once, companies must protect their employees through personal protective equipment, now supported by Resco digital tools for inspections and record keeping. And that’s where PPE comes into play.

In this article, we will delve deeper into the importance of PPE safety, the different types of PPE, and the industries that require it.

We will also explore the challenges associated with ensuring proper PPE use and the role of employers in promoting a safe and healthy work environment.

But before we do so, we need to answer one question…

What is PPE?

Personal protective equipment, or PPE, is any clothing or gear that forms a barrier between a worker and a hazard. It stops injury, illness and infection when contact with physical, chemical or biological risks cannot be engineered out. Hard hats, safety glasses, gloves, steel toe boots and respirators are common examples, and industries such as construction, manufacturing, agriculture and healthcare rely on them every day. Employers must supply the right items, train people to use them and make sure they are worn whenever other safety controls do not go far enough.

OSHA requires all businesses to provide employees with appropriate PPE and training to go with it wherever necessary. As an employer, you’re responsible for informing your workers regarding the following:

- When and where PPE is required in the workplace.

- What type of PPE to use in a given situation.

- How to properly put on, adjust, and remove their PPE equipment.

- How to care for, maintain, and dispose of PPE equipment.

- The PPE’s limitations.

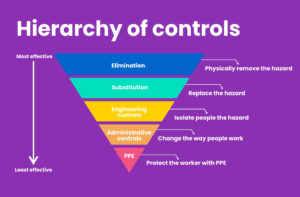

However, it’s important to mention that PPE should not be the end-all-be-all of your company’s safety measures.

According to the National Institute for Occupational Safety and Health (NIOSH), PPE should be the last line of defense to prevent harm. Consequently, combine it with other control measures to ensure a safe and healthy work environment.

What are the benefits of PPE?

Apart from the obvious benefits (i.e., preventing unnecessary deaths), PPE can improve your and your employees’ lives in a variety of ways.

Here are a few examples:

Benefits of PPE for employers:

- Reduced workers’ compensation claims: PPE can help prevent workplace injuries, reducing the number of workers’ compensation claims filed and the associated costs.

- Higher productivity: Employees who feel safe and confident in performing their job duties are more likely to work efficiently and productively.

- Improved compliance: Compliance with workplace safety regulations is critical to avoid fines and legal issues. Providing PPE to employees demonstrates a commitment to safety and compliance with relevant regulations.

- Fewer missed hours: Injuries and illnesses that result from workplace hazards can cause employees to miss work, resulting in reduced productivity and increased costs. By providing PPE, employers can reduce the likelihood of workplace injuries and illnesses, thereby decreasing absenteeism.

Benefits of PPE for employees:

- Reduced risk of injury: PPE helps protect employees from workplace hazards, reducing the risk of injury and illness.

- Increased confidence: When employees feel protected and safe, they are more confident in performing their duties, resulting in increased job satisfaction and productivity.

- Better health: PPE can prevent exposure to harmful substances, such as chemicals or infectious diseases, promoting better health and preventing illness.

- Longer career: PPE can prolong an employee’s career by reducing the risk of injury and illness, allowing them to continue working longer.

Conducting a hazard assessment

The first step to creating a safe working environment is understanding the potential hazards your employees may encounter.

And to gain that understanding, you need to carry out a hazard assessment, which will not only reveal threats but also help remove them altogether or at least prevent them with PPE.

Last but not least, a hazard assessment will also inform your decisions regarding the level and type of PPE your employees need to stay out of harm’s way. So, how do you conduct a hazard assessment?

Step 1) Select your tools

It’s best to combine your inspections with other tools, like surveys and checklists. Surveys are perfect for gathering data from different people and departments in your company.

Meanwhile, checklists will streamline your inspection process by clearly outlining what you’re looking for and making it easy to track all variables.

You should also consider whether you want to use paper-based media or a digital option for your Health and Safety Assessment.

While paper may be easy to come by and is relatively inexpensive, it comes with its fair share of limitations. It’s easily damaged or lost and requires a lot of effort to distribute, track, and evaluate.

If you decide to go digital, Resco Inspections+ lets frontline staff open a prebuilt incident report on any phone or tablet, even when offline. They can add photos and signatures on the spot and email a branded PDF the moment they reconnect.

You can learn more about this transformation on the example of Stony Valley. Being paper-intensive for their safety processes in the field, their technicians struggled with lost, dirty, and damaged copies of paperwork, as well as limited access to technology in remote areas.

Integration of digital assessments allowed field staff to capture information digitally and eliminated the need for physical paperwork. This digital transformation helped the company streamline health and safety assessments and document storage, avoiding further losses due to unforeseen events like floods.

Step 2) Identify hazards

Start your assessment by walking around the workplace, observing your employees, and looking for potential hazards, like falling or rolling objects.

You can also further involve your workers by discussing their day-to-day tasks with them and letting them suggest areas for improvement.

Then, categorize these threats into OSHA’s basic hazard categories:

- Penetration

- Compression (roll-over)

- Chemical

- Heat/cold

- Harmful dust

- Light radiation

- Biological

Once done, your hazard assessment should look something like this:

Choosing appropriate PPE

Not all PPE is created equal. Each piece of equipment varies in its best use, as well as size, manufacturing quality, comfort, and more. You’ll want to consider these variables to ensure your employees are safe and sound and that your compliance with the law is air-tight.

Below, we’ll discuss how to choose the appropriate PPE for each situation, ensure its used effectively, and that you avoid any potential legal trouble.

Choosing the right PPE type for hazards

You can choose the necessary PPE equipment for each area or task based on the hazards you find in your workplace. You’ll want to look at one or a combination of the following preventative measures:

1. Respiratory protection: Use face masks and respirators (e.g., N95 respirators) to protect the respiratory system from airborne particles, including dust, gases, and viruses.

2. Eye and face protection: Use safety glasses and goggles to protect the eyes from flying debris, chemicals, and other hazards that may cause eye injuries. Or, use face shields to protect the face, including the eyes, nose, and mouth, against splashes, sprays, and droplets.

3. Hand protection: Gloves, made of various materials such as latex, vinyl, or nitrile, protect the hands from chemicals, cuts, and abrasions. You can use heat-resistant gloves to protect against burns and hot surfaces and cut-resistant gloves made of materials such as Kevlar to protect against cuts and lacerations.

4. Head protection: Use hard hats to protect the head from falling objects and impacts. If the threat is lower, you can use bump caps that are lighter than hard hats to protect against minor impacts and scrapes.

5. Foot protection: Safety shoes and boots protect the feet from falling objects, punctures, and slips. But electrical hazard (EH) boots provide additional protection against electrical hazards.

6. Hearing protection: Use earplugs and earmuffs to protect the ears from loud noises that may cause hearing loss.

7. Skin protection: Coveralls and other types of protective clothing are used to protect the skin from exposure to hazardous substances, including chemicals, radiation, and biological agents (i.e., hazmat suits, heat suits, etc.).

Choosing the best PPE for employees

When selecting PPE for your team, you should consider several factors to ensure that it provides adequate protection and is comfortable for prolonged use. Some of the critical factors include the following:

1. Fit: Make sure the PPE you select is the right size and shape for each team member to ensure a secure and comfortable fit to maximize its effectiveness.

2. Comfort: PPE that is comfortable to wear encourages workers to wear it consistently, reducing the risk of injury. Look for lightweight, breathable materials that will not cause discomfort during prolonged use.

3. Durability: Choose PPE made from high-quality materials that can withstand the wear and tear of daily use.

4. Compatibility: Ensure your PPE matches other workers’ equipment and clothing. For example, hard hats should fit comfortably over headsets, and safety glasses should fit over prescription glasses.

5. Maintenance and cleaning: PPE must be cleaned regularly to ensure its effectiveness. Choose easy-to-clean and maintain equipment, and train your team to properly care for their PPE.

6. Cost: PPE can be expensive, but it’s essential to prioritize worker safety. Consider the long-term costs of PPE when selecting, including replacement, maintenance, and cleaning costs.

Choosing the best PPE for legal compliance

Last but certainly not least, we need to look at how PPE can help you protect your company from legal trouble just as much as your employees from harm.

There are three core steps to this process:

1. Know the regulations: Familiarize yourself with the PPE standards and regulations that apply to your industry or jurisdiction. These may include Occupational Safety and Health Administration (OSHA) standards, National Institute for Occupational Safety and Health (NIOSH) guidelines, and industry-specific regulations.

2. Look for certified products: Look for PPE products that have been certified to meet the appropriate standards. Look for certifications from reputable organizations, such as ANSI, ASTM, and CE.

3. Keep detailed records that prove every item of PPE meets current standards: For instant audit evidence, Resco Docs+ turns each inspection or incident form into a branded PDF report and stores it automatically, so you can retrieve proof of compliance in seconds.

4. Check for compliance markings: Look for markings on the PPE that indicate that it complies with the appropriate standards. These may include codes or symbols that indicate the level of protection provided, the type of hazard the PPE is designed to protect against, and the name of the certifying organization.

Next steps with digital PPE safety

Personal protective equipment is only as strong as the processes that support it. Once you have mapped your hazards and trained every worker, two Resco apps help you keep the system running smoothly and prove compliance at audit time:

- Inspections+: Create ready made hazard and fit-test checklists that technicians complete on any phone or tablet, even offline.

- Docs+: Turn each completed inspection into a branded PDF stored automatically, so you can retrieve proof of compliance in seconds.

With inspections captured in the field and reports filed instantly, you lower claim costs, strengthen legal defence and give crews the confidence to stay productive. Book a short demo and see how fast you can move from paper based binders to a fully digital PPE safety programme.