Efficiency is one of the most critical core values of manufacturing. You want to produce as much as possible while keeping your resource spending at a minimum. But even a single malfunction in your assembly line or utilities can throw a wrench into your operation – literally. The resulting unscheduled downtime and reactive maintenance cause delays and can significantly cut into your bottom line.

What is scheduled maintenance?

Scheduled maintenance is any maintenance task planned and assigned ahead of time to specific personnel within a set timeframe. Its main purpose is to prevent unexpected equipment failures and optimize the efficient use of company resources. Scheduled maintenance clearly defines what needs to be serviced, why it is necessary, how it will be done, who will perform it, and exactly when it will occur.

With tools like Field Service+, you can easily manage and simplify the entire workflow from initial planning to final execution.

Scheduled maintenance is the result of two co-reliant activities – maintenance planning and scheduling. Although the phrases are often incorrectly used interchangeably, they describe different things.

With scheduled maintenance, you can take full control of your facility’s upkeep, ensuring that the right people do the right work at the right time. And in this article, we’ll show you how to do that, as well as discuss the following topics:

- What is scheduled maintenance

- The difference between maintenance planning and scheduling

- The benefits of scheduled maintenance

- What you should consider before creating a maintenance schedule

- How to schedule maintenance

- How to make maintenance scheduling easier

What is the difference between maintenance planning and scheduling?

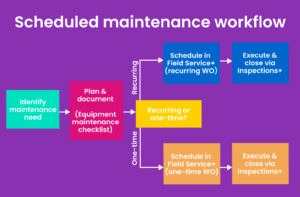

Maintenance planning tackles the “what,” “why,” and “how.” It identifies which assets need attention, clarifies the purpose of each task, and spells out the required parts, tools, and procedures. With the help of Inspections+ you can easily create standardized checklists and detailed work instructions, ensuring technicians have clear guidance on their tasks and objectives.

Maintenance scheduling answers the “who” and “when.” It assigns the right technician and slots the job into the most efficient time window, minimizing disruption to production. Field Service+ (with its drag-and-drop Schedule Board) makes it easy to match skills to tasks, visualize availability, and keep everyone in sync, online or offline.

What are the benefits of scheduled maintenance?

If you choose to incorporate scheduled maintenance into your company’s operations, you can expect to enjoy several benefits and quality of life improvements. These include:

- minimized external & maximized internal resource use

- improved manufacturing efficiency

- higher employee productivity

- lower operating costs

- fewer breakdowns

- reduced downtime

- quicker workflow

These benefits are the consequence of careful time and workforce management. Some of the basic principles of scheduling are:

- planning multiple service tasks for a single piece of equipment at the same time

- assigning the most qualified internal technicians to their respective specialties

- effectively utilizing planned downtime to carry out repairs

However, there is more to scheduled maintenance than just these three techniques. If you really want to take your facility’s efficiency to the next level, there are several things you need to do first.

What to consider before creating a maintenance schedule

Creating a practical maintenance schedule takes time and effort. Sometimes the work can be so complex that companies choose to hire specialized planners and schedulers. However, nowadays, you can achieve similar results with a handy manager and some good software.

Regardless of what you choose, there are things you’ll need to consider. These include:

- Priority of the maintenance task

Naturally, you should take care of the most pressing issues first. Tag work orders by priority in Resco Field Service+; the Schedule Board highlights critical tasks so they never slip through the cracks. - Availability of technicians and their skillsets

Consider which of your employees would fit the job the best. Assign your technicians to work orders that fall within their specialties to shorten service time and boost morale. - Operating hours and planned downtime

Try to fit your repairs into time slots that require the machinery to be turned off anyway. This will help you reduce unnecessary downtime and lead to higher productivity. - Date of the work order’s submission

Although more severe or dangerous issues always have to take priority, there is a case for not repeatedly pushing the same tasks back. Unaddressed malfunctions can become more serious over time, and the people who have to deal with them will only grow more unhappy. So try to find a balance in your prioritization.

How to schedule maintenance

Once you’ve assessed your current work orders from all necessary aspects and points of view, it’s time to create a maintenance schedule. This process can be broken down into several steps:

- Align with your team

If you want to succeed, you need to get the rest of your team onboard. Gather coworkers and present your plans. Outline the benefits a maintenance schedule can offer your company. - Analyze your current situation

Continue working with your team. Ask the heads of different departments for their view of your company’s current situation. Compile an overview of your backlogged maintenance work, and start ordering them as described above (by priority, time sensitiveness, etc.). - Begin with maintenance planning

In the previous steps, you’ve established what work needs to be done, so now your job is to lay the groundwork for your new and improved processes. To do this, you’ll need to ensure that your workers have reliable documentation regarding the maintenance process and that their roles and responsibilities are clear. - Implement the new schedule

Once everything’s clearly defined, it’s time to put your maintenance schedule into practice. Make sure your service workers can access it, and from that point on, let them do their job. Depending on the tools you choose for this job, this might be easier said than done. - Review and improve

Nothing is made perfect on the first try. Set up sessions to review your performance. Look for aspects of your new maintenance organization where there’s room to grow and keep on improving. But don’t forget to celebrate the victories you achieve – creating and keeping to a maintenance schedule is hard work, and people deserve recognition for their effort. To support continuous improvement, using structured digital checklists can help standardize task execution and track results across time.

How to make maintenance scheduling easier

Like with anything in life, the difficulty of maintenance scheduling largely depends on the tools you choose for the job. In the past, planners, schedulers, and managers had to do much of the work manually while relying on paper-based solutions and convoluted lines of communication.

Luckily, nowadays with digital solutions like the Schedule Board in Field Service+, creating and keeping to a maintenance schedule is a breeze. This tool allows you to assign tasks based on skills and availability, monitor job completion, and manage your entire maintenance team in one place.

For technicians in the field, pairing this with Inspections+ enables digital checklists and standardized reports, while Docs+ ensures they always have the latest manuals and documentation at their fingertips, even offline.