Lockout/tagout (LOTO) keeps workplaces safe and meets compliance standards, but it’s still one of OSHA’s most frequently cited safety violations. Using Resco digital tools to manage your LOTO procedures helps minimize risks, prevent injuries, and makes the whole process easier. Let’s look at how you can implement LOTO according to guidelines from OSHA and CDC.

What is a lockout/tagout procedure?

Lockout/tagout (LOTO) is a safety procedure used to ensure equipment is completely powered off and secured during maintenance or servicing. Authorized personnel follow specific steps to isolate all energy sources, release stored energy, and place locks or tags on switches and valves. This prevents machinery from unexpectedly starting and protects workers from injury.

LOTO procedure also includes placing tags and locks on energy isolation devices (e.g., power switches, control valves) to prevent their unauthorized use during the servicing of a machine.

This process ensures that the equipment is shut down and inoperable until workers complete the planned action.

However, do not confuse lockout and tagout as performing a similar function. The lockout device stops employees from working on the equipment.

Meanwhile, the tagout tells them not to work on the machinery. In short, both are hardcore protection against unsafe equipment where the lockout device is the first layer, and the tagout device is the second.

With Resco Inspections+, technicians can simplify and streamline LOTO processes by following safety checklists directly on mobile devices. Inspectors can verify each lockout/tagout step even without internet access, ensuring consistent accuracy and compliance.

When to use tags and when to use locks?

Locks are used when the equipment is required to be locked physically. It’s used as an energy-isolating device that turns off the energy source of the machine to secure the device in a safe position.

In the meantime, tags come perfectly handy where locks can’t physically lock out energy-isolation devices.

Along with that, they also provide crucial information like who approved the lockout, why it was approved, and also keep you up to date about the current status and time.

Colors of lockout locks and tags

Till now, OSHA has provided no standardized color-coding system for lockout locks and tags. However, there is a generally used system regarding the typical color codes:

- Red tag = Personal Danger Tag (PDT)

- Orange tag = group isolation or lockbox tag

- Yellow tag = Out of Service Tag (OOS)

- Blue tag = commissioning and test tag

- Red lock = used to lockout equipment during a maintenance procedure

- Orange lock = used to indicate that it is safe to perform service procedure

- Yellow lock = used to lockout equipment before servicing by an affected employee

- Blue lock = used in place of orange lock for lockboxes having 6+ isolation points

Guidelines & standards

The American National Standards Institute (ANSI) published its first-ever lockout/tagout practicing guidelines in 1982. The purpose was to deliver safety precautions needed when employees were doing maintenance of hazardous energy sources.

Then, in 1989 those guidelines became the Occupational Safety and Health Administration (OSHA) regulations. If we talk about the guidelines prescribed by OSHA, they cover all energy resources from mechanical to thermal, including electrical, hydraulic, pneumatic, and chemical. And these are crucial for the maintenance activities of manufacturing plants.

As far as LOTO is concerned, its name itself indicates that it used two approaches to ensure the safety of employees during maintenance activities.

These lockout and tagout procedures limit energy access to equipment and show warning signs to notify employees about upcoming hazards.

Who needs to comply with LOTO OSHA standards?

Most companies in the U.S. need to follow the Occupational Safety and Health Administration’s (OSHA) regulations, which applies to nearly all private businesses across the country and its territories.

Employers must ensure their workplaces have the right safety measures in place and actively reduce hazards that could harm employees physically or mentally, immediately or over time.

Possible Hazards Checklist

Download a free Possible Hazards Checklist template to significantly improve your workers’ safety by completing the hazard scans

Importance of LOTO

Safety practices in a plant’s operations are crucial to safeguard employees from avoidable harm. A shocking number of tragedies can occur while the maintenance procedure and LOTO implementation can ward off such tragedies efficiently. It basically blocks the energy sources of equipment from activating during maintenance to reduce the risk of injury.

Lockout procedures prevent equipment energy sources from activating when they should not, particularly during maintenance when employees are at risk of injury or death.

Effective lockout-tagout procedures also moderate downtime and protect costly equipment by ensuring it is shut down properly.

Hazardous risks that can be prevented

These are the three situations; workers are at risk of accidents.

- Maintenance procedures

- Cleaning Machinery

- Removing items stuck in machinery

These underlying situations require coworkers to work more closely with the moving parts on equipment. But, if any kind of mishandling occurs, there is a high risk of injuries.

With proper LOTO, here are some examples of incidents that can be averted:

- During maintenance or examination, getting suffocated if the machine starts moving or re-energizes

- Electrocution due to not cutting off the power supply ahead of the time

- Getting fractures or losing a limb due to moving parts of the machinery

- Getting the body part crushed under the moving machinery

- Third-degree or lethal burns because of pouring hot liquids or toxins that weren’t blocked during machine maintenance

Types of energies LOTO prevents

When you prepare the equipment for maintenance, often hazardous energies are released. These energies can be:

- Chemical

- Pneumatic

- Electrical

- Mechanical

- Hydraulic

- Thermal

For the workers, the energy sources in machines and equipment that count electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other sources are unsafe. If during the maintenance procedure there is an unexpected startup or release of stored energy, it can cause drastic effects or even the death of the workers.

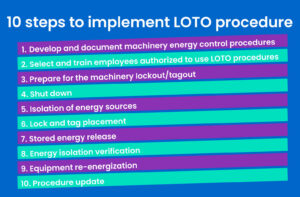

10 steps to implement lockout/tagout (LOTO) procedure

Stage: Preparation of a lockout/tagout program

1. Develop and document machinery energy control procedures

To begin with a LOTO procedure, you need to identify devices and machinery to which hazardous energy control programs will apply. Document a step-by-step process for correct shutting down and restarting of this equipment, include its location and details that will help eliminate possible dangerous actions. All necessary lockout/tagout documentation, including OSHA guidelines and machinery shutdown procedures, can be securely stored and instantly accessed with Docs+. This ensures that your team always works with the most recent instructions, available even in offline environments.

You should be as specific as possible in this step as the documentation will provide fundamental guidelines to authorized employees. Depending on the complexity of the equipment and its application, proper procedure documentation may vary from one to many pages.

OSHA explains what should be included in the documents as follows:

- A statement on how to use the procedures;

- Specific procedural steps to shut down, isolate, block, and secure machines;

- Specific steps designating the safe placement, removal, and transfer of lockout/tagout devices and identifying who has responsibility for the lockout/tagout devices; and

- Specific requirements for testing machines to determine and verify the effectiveness of lockout devices, tagout devices, and other energy-control measures.

2. Select and train employees authorized to use LOTO procedures

Every worker should have a clear understanding of when energy control procedures apply, but personnel who perform the maintenance should be also qualified to use the procedures. The authorized employees must be trained to understand the hazards and how to implement safety measures to mitigate risks.

Stage: LOTO application

3. Prepare for the machinery lockout/tagout

Before the actual shut down of machinery, authorized personnel have to notify all affected employees about planned maintenance or servicing, and that energy control procedures will be applied.

Provide exact information about the time and duration of the maintenance and update them if any changes were made during the process. This step is necessary to prevent unexpected attempts of equipment re-energization.

4. Shut down

In this step, an authorized employee will shut down the equipment using a standardized procedure (e.g., power switch) documented in the guidelines.

5. Isolation of energy sources

Workers then locate and isolate all energy sources of the equipment. This may include actions such as turning off power cables or shutting a valve.

6. Lock and tag placement

After full isolation of machinery from energy sources, authorized personnel attach lockout and tagout devices to parts that can be used for re-energization. This can include electric breaker panels or control valves. The locks and tags are necessary to prevent manipulation of equipment from unauthorized employees. Technicians can use digital forms provided by Resco Forms+ to quickly record lock and tag placements. Each lockout step, tag ID, and worker signature is digitally logged, reducing paperwork and increasing accountability and accuracy.

Each individual authorized for locking or tagging a machine should use signed or person-specific locks or tags, so everyone knows who placed them.

A worker who places the devices should be also the only one allowed to remove them according to OSHA guidelines.

7. Stored energy release

Even after proper shutdown and equipment lockout procedures implementation, machines can possess safety risks because of the stored residual energy.

For example, spring tension, heated liquids, or venting gases could be accidentally released during maintenance and thus need to be handled beforehand. Workers should also secure all moving parts that posses safety hazards throughout the maintenance.

8. Energy isolation verification

In the last step before the maintenance itself, authorized personnel should inspect the proper application of the previous steps.

The machinery is shut down, all energy sources are isolated, locks and tags are in place, and residual energy is released. After the successful inspection, workers can proceed with maintenance.

Stage: LOTO removal

9. Equipment re-energization

Upon completion of maintenance, Field Service+ enables technicians to immediately notify supervisors that equipment is ready for safe re-energization. This instant status update minimizes downtime and prevents premature or unsafe equipment restarts.

10. Procedure update

The best practice of the lockout/tagout procedure includes at least annual updates of the documentation and equipment inspections.

Make sure your guidelines are always up-to-date and follow the latest OSHA standards.

Bonus step:

Process standardization and Health & Safety assessment with mobile inspection software

Inspection software can automate various processes within the LOTO procedure thanks to checklists, mobile forms, inspection reports, or appointment management.

For example, authorized personnel can use mobile software throughout all the steps of shutting down and re-energization of equipment.

With a tailor-made lockout/tagout checklist, they can check if all necessary steps were completed correctly and in the right order.

Digitalization of these processes also enhances data collection standardization and offers real-time updates for managers and supervisors, who can further streamline their lockout/tagout procedures.

Furthermore, the free 30-day trial of resco.Inspections comes with a free OSH risk template that you can easily customize for LOTO scenarios as well.

Violations

If you violate LOTO standards, there is a penalty that you must pay, so beware of these most common lockout tagout violations:

- Failing to classify and cut off all energy sources

- Failing to shut down the equipment

- Not capable to de-energize

- Incapable to drain residual energy

- Unable to establish a lockout tagout program

- Incompetent of developing and enforcing a lock out tag out policy

… and many others.

Responsibilities

In a work setting, each individual is responsible for the lockout/tagout program.

Management

From drafting to updating lockouts, management is responsible for handling all these procedures. Along with that, they are also involved in identifying employees, machineries, equipment and all other processes involved in the program.

Supervisor

Supervisors are accountable for distributing protective equipment, hardware, and any appliance, along with ensuring employees properly use them.

In addition, they are also involved in ensuring that equipment-specific procedures are established for the machines, equipment and processes in their area.

Lastly, they must make it certain that the employees are strictly following the lockout procedures where required.

Authorized Individual

Authorized individuals are required to follow the developed procedures and report any problem associated with those procedures.

Starting with a LOTO program

OSHA standards prevent workplace injuries and fatalities through clearly defined safety procedures like lockout/tagout (LOTO). By digitizing your LOTO workflows with Resco Inspections+, you can achieve OSHA compliance, enhance safety, and reduce the risk of human error. Whether you’re just getting started or refining your existing safety processes, Resco’s mobile-first solutions offer a simple way to standardize and streamline your operations anytime, anywhere.

Possible Hazards Checklist

Download a free Possible Hazards Checklist template to significantly improve your workers’ safety by completing the hazard scans