Increase operation efficiency and safety

Minimize errors, meet quality standards, and follow lean production principles with digital instructions, manuals, and standardized operating procedures. With resco.Guides, your technicians and production operators have them always at hand.

Ensure continuous improvement and preserve tribal knowledge

The aging workforce is a growing problem of traditional industries like manufacturing maintenance. Preserve the experience of your experts and identify repeating issues by building institutional knowledge around your workflows that will help a new generation of technicians to thrive.

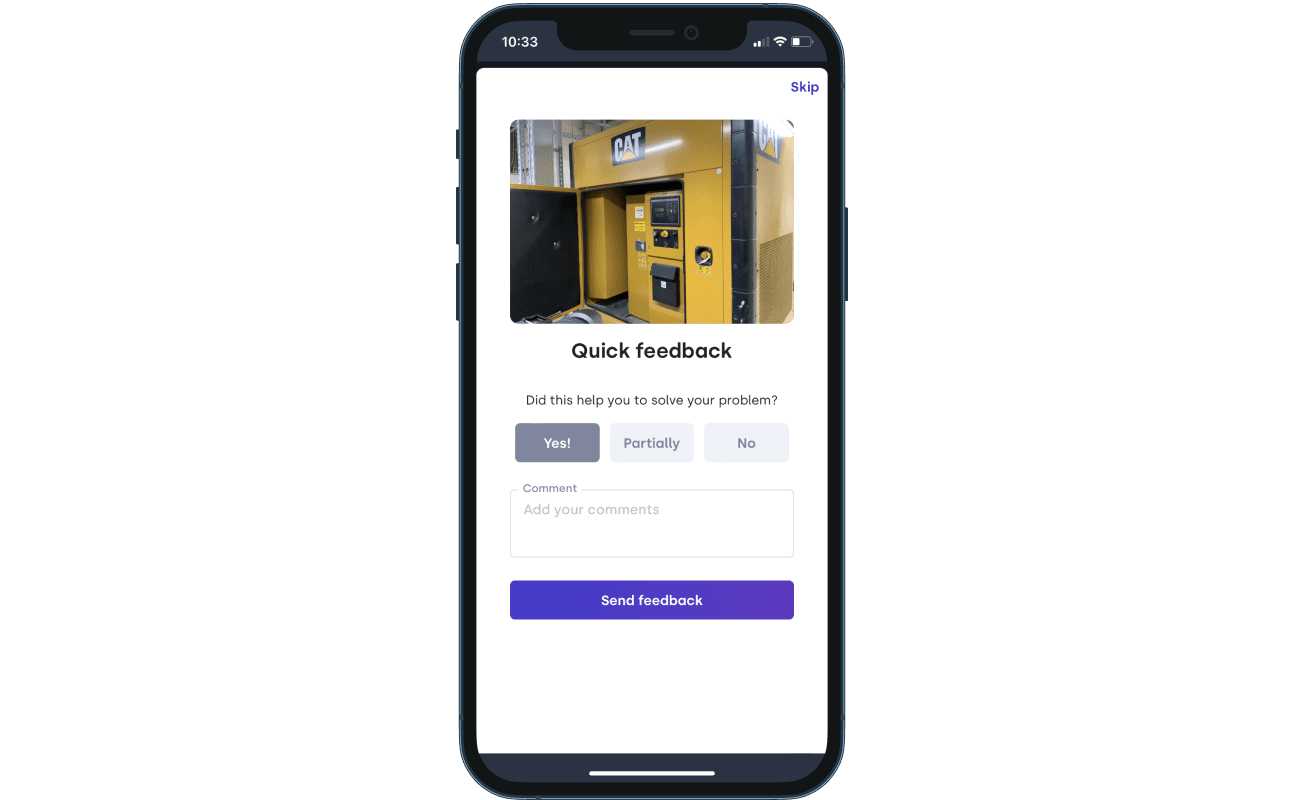

Collect feedback on-the-job

Give your field workers a user-friendly way to contribute to better and up-to-date guides. Get instantaneous feedback right from the field to quickly identify missing or incorrect instructions and ensure agile process improvement.

Versatile in data management, simple to use

1.

Collect critical knowledge directly from technicians and operators, in a minute, via phone, tablet, or desktop

2.

Create, manage, and distribute work instructions in various formats via intuitive interface

3.

Access knowledge quickly on-site through QR codes and search functionality

4.

Utilize all available guides to complete tasks efficiently and without mistakes or delays

5.

Evaluate instructions, rate your materials, and upgrade the database to ensure continuous process improvements

Don’t lose the hard-earned knowledge. Preserve it. Use it. Master it.

MS Dynamics 365

Field Service

Sales

Dataverse

iOS

Android

Windows

Web

Mobile

Tablet

Desktop

RealWear